A Side Quest While On The Quest to Define Supply Chain Visibility

Enough about IoT, or How I learned to stop worrying and love real-time tracking

This edition of Rough Terrain isn’t brought to you by anyone (but hit up ya boy if you feel like sponsoring). Instead, I’m giving a shout-out to a small business that I love -Green Rascal. It’s a family-owned company that sells spinach and kale powder that they grow themselves. I love using their powders to sneak more greens into my daily smoothie. They are supposedly for getting kids to eat healthier, but I’m technically a man child, so I count too! Check them out, they’re great!

Or, buy some of the best coffee in the world :)

Pardon the interlude between my posts opining on what Supply Chain Visibility (SCV) is, but there’s been a thought percolating in my brain about one specific subject and I need to get it out. I swear I’ll get to the 3rd step, Action, soon. Probably.

At my day job, not a week goes by that I don’t get asked about Internet of Things (IoT) devices. Sometimes it’s multiple times a week. Sometimes multiple times a day. It doesn’t help that there’s a flood of news about it. I feel like Captain O’Hagan from the movie Super Troopers:

What’s everyone’s deal, you ask? Why do they care so much about those little thingys that get attached to freight shipments? Did they eat too many of the snozzberries?

The short answer is that people are eager for solutions to the problems I’ve talked about in previous articles about SCV. Lack of observability into segments in their supply chain and lack of sharing of those observations with relevant parties.

IoT seems like the kind of tool that could solve these problems. Stick some nifty tracking devices to the side of the 40 ft metal box that has a bunch of your stuff in it and then boom! Observations a’ plenty and all immediately accessible. It looks like a silver bullet for many supply chain managers, a way out of the hell that is chasing vendors, suppliers, and carriers for updates. You just go around all those folks and get the data straight from the front lines. SCV solved! No wonder people don’t stop asking me about it.

The long answer requires more memes (which, let’s be honest, is why you’re here).

First, I think we need to step back and examine the world we live in today. It’s 2022 and yet the industry of trade, which is perhaps the oldest industry there is (not to be confused with the oldest profession…), lags significantly behind other industries in its adoption of technologies. Pen and paper are still commonplace in this industry and the dominant software is Excel. I often half-joke with my team that the job of a Product Manager in logistics is to make something that is just good enough to get people to stop using Excel.

see?

Remember that fictional grocery store that purchased coconuts from my previous articles? Imagine being the inventory manager of the store. She has to chase status and location updates on those coconuts as they are grown, packed, shipped, and received. She tries to maintain a semblance of understanding of those coconuts’ status, as well as the hundreds or thousands of other items she’s trying to stock. Her life is one of compiling together the many emails, Excel files, and other reports she gets from her suppliers, vendors, and carriers involved (time for a TMS and ERP, right?)

Contrast her experience at her job with her experience as an average consumer in 2022. After she bangs her head against her desk most of the day, she goes home. Perhaps she doesn’t want to cook that evening, so she orders food from DoorDash or InstaCart. From the moment she places the order, she knows down to the minute when it will arrive at her house, with frequent updates as the meal is prepared and out for delivery.

There is a stark difference between the tracking of things she purchases for her store and the tracking of goods she purchases for herself. That contrast gnaws at her day after day. Why the hell is it so hard to know where stuff is in her supply chain, which is orders of magnitude larger in terms of cost and importance, than her dinner order for a chicken Caesar wrap? She should be able to have the precise location and status of her coconuts with the same ease and simplicity as her DoorDash order.

But she doesn’t. Instead, she spends her days trying to cobble together an understanding of what is and isn’t going right across her many orders and shipments.

She is, rightfully, PISSED.

Who’s responsible for this unyielding expectation to know the precise location and status of our freight at any time?

This guy:

Wait, that’s not the picture I wanted. I meant, this guy:

DAMN IT. Sorry, no, not that picture, I meant THIS GUY:

There are a bajillion articles about the “Amazon Effect” and its impact on commerce and logistics. Everyone knows how things like Prime’s 2-day free shipping have pushed retail into an ever-escalating war of speedy logistics. Less has been written about the carry-over of the Amazon Effect to other industries. The expectation of always knowing when your package will arrive at your doorstep is no longer confined to purchases on e-commerce sites. It has bled into all facets of all industries.

Ours included.

Justifying this difference in experiences between a retail purchase as a consumer and a wholesale purchase as a shipper is getting impossible. It’s like driving a Ferrari on the evenings and weekends but driving a ‘84 Malibu on the weekdays. It doesn’t make sense, and the excuses aren’t tolerated anymore. People are demanding Prime-like Supply Chain Visibility.

Thus, the daily asks of me about IoT. And my desire to pistol whip said people asking.

Because on its surface, IoT is how you get to a Prime-level of SCV. Real-time tracking gives you the location of your goods so you can know with certainty where your stuff is. Or so many in our industry believe. Debating this idea is one of the trade industry’s favorite past-times.

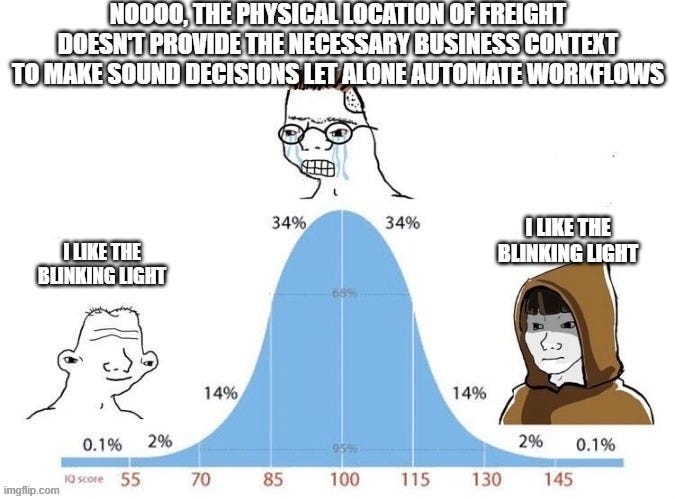

Historically, I was in the camp that opposed it. I didn’t see the value of it for most freight movements. For the majority of a shipment’s voyage from somewhere to somewhere else, I thought people didn’t need to know the precise location nor have that location constantly updated. Instead, I thought that by and large, the industry really only needs moderately precise up-to-date locations of the goods they are interested in. Unless the freight is directly under your control, your level of necessary fidelity isn’t high. No one besides the terminal operator really needs to know in what precise stack the container is, right? Knowing that a ship in the middle of the ocean has moved a few nautical miles doesn’t really help anybody, right? Nobody besides the operating carrier needs to know the precise cell the box is in the hold, right?

“What’s the point of a blinking light on a map if you can’t do anything about it?” I scoffed to myself, thinking I knew more about supply chain management than people with 10 times as much experience.

But as I’ve thought more about it, I’ve changed my position. Now I like the blinking light. Not because people need to know the precise location for the entirety of its journey. It’s because of the peace of mind that comes from being able to get the most up-to-date information about your goods any time you want it.

You see, our friend the stressed-out grocery store inventory manager doesn’t actually want to watch a blinking light on a map that represents her coconuts while they sail across the ocean. She’s got hundreds of other orders and hundreds of other shipments trying to occupy space in her brain. She ain’t got time to check each one constantly.

She needs to know which ones require her attention at that specific point in time. She needs to manage by exception. But she can’t do this if she’s spending lots of time chasing statuses and location updates. This is the same as her DoorDash order. She’s not watching the live location of her order on a map (unless she’s super hungry to the point of rage, or what we call “mungry” in my house). But having the optionality to check whenever she pleases gives her peace of mind. Coupled with the delivery company’s system that will alert her of any issue that arises, she can effectively ignore the progress of her order unless she’s warned otherwise.

Getting IoT devices attached to her shipments open the possibility of having that same option to check and the opportunity to be alerted in real-time if something goes wrong. No more calls, no more f*cking Excel files. Finally, Prime-level SCV.

Maybe.

I’m bullish on IoT and all types of real-time tracking of freight shipments. I think it represents a big value unlock for everyone in the industry. I do think it can move us towards managing by exception, real-time alerting if there’s an issue, and giving folks peace of mind by allowing them to always know where their stuff is. And there’s a part of me that is cackling like Snidley Whiplash over the thought of being able to have an independent time-based stream of location data for all the shipments I care about as a way to double-check what I get from all the carriers, ports, ground handlers, etc.

But I don’t think IoT devices alone can get us to the Prime-level SCV we all so badly desire. Because while they’re great at telling you the location of things, that’s just half the battle. The other half is the status of those things. IoT can help with some of that, like having temperature measurements on refrigerated shipments. But there are statuses for freight shipments that are currently impossible to physically measure. Things like having holds on the shipment because it hasn’t cleared customs. Or knowing how many days are left before you start accruing demurrage fees. Or being able to generate an accurate update for when the goods will finally arrive at your warehouse because of those pesky holds.

Nevertheless, I’ll take it. It’s a big step forward. If you’ve got the data that lets you manage by exception, at least for location-based exceptions, that’s a big leap forward for many companies that ship freight.

The freight industry needs to recognize the fundamental change in customer expectations that have come as a result of the Amazon Effect. We’re not going back. Customers’ demands for real-time awareness will only continue to increase. The disparity between what a supply chain manager’s experience is doing their own personal online shopping and their experience with their 3PL and carriers is a daily stark reminder of our industry’s failure to adapt.

So get ready engineer managers for the amount of data you’re going to have to stream through your application. Get ready, product designer, for how to effectively filter all this data into formats that make users of your application effective and not get overwhelmed. But most of all, get ready, all you asset owners - every truck, ship, railcar, barge, donkey, blimp, etc. is going to need to constantly transmit its location and status in an easily accessible manner. It will be a non-negotiable requirement in due time.

In conclusion: I like the blinking light.